Machining advanced materials like titanium, Inconel, and composites demands precision, expertise, and the right approach to achieve professional results consistently.

🔧 Why These Materials Are Game-Changers in Modern Manufacturing

The aerospace, medical, and energy industries rely heavily on materials that can withstand extreme conditions. Titanium alloys offer exceptional strength-to-weight ratios, Inconel provides unmatched heat resistance, and composite materials deliver versatility that traditional metals cannot match. However, these performance advantages come with significant machining challenges that separate amateur operations from professional workshops.

Understanding the unique characteristics of each material is the foundation of successful machining. Titanium’s low thermal conductivity causes heat to concentrate at the cutting edge rather than dissipating through the workpiece. Inconel’s work-hardening properties mean the material becomes harder as you machine it. Composites present entirely different challenges with their heterogeneous structure combining fibers and matrix materials.

The Titanium Challenge: Taming the Wonder Metal ✈️

Titanium has earned its reputation as one of the most difficult materials to machine, but understanding its behavior transforms this challenge into an opportunity. The key lies in managing heat generation and preventing work hardening during the cutting process.

Cutting Parameters That Actually Work

Professional machinists know that titanium requires a delicate balance of cutting speed and feed rate. Unlike steel, you cannot simply increase speed to improve productivity. Lower cutting speeds between 50-80 surface feet per minute (SFM) combined with higher feed rates produce better results than aggressive speeds with light feeds.

The reasoning behind this approach relates to titanium’s thermal properties. Higher feeds reduce the time heat stays concentrated in any single area, while lower speeds prevent excessive temperature buildup. This combination minimizes work hardening and extends tool life significantly.

Tool Selection Makes All the Difference

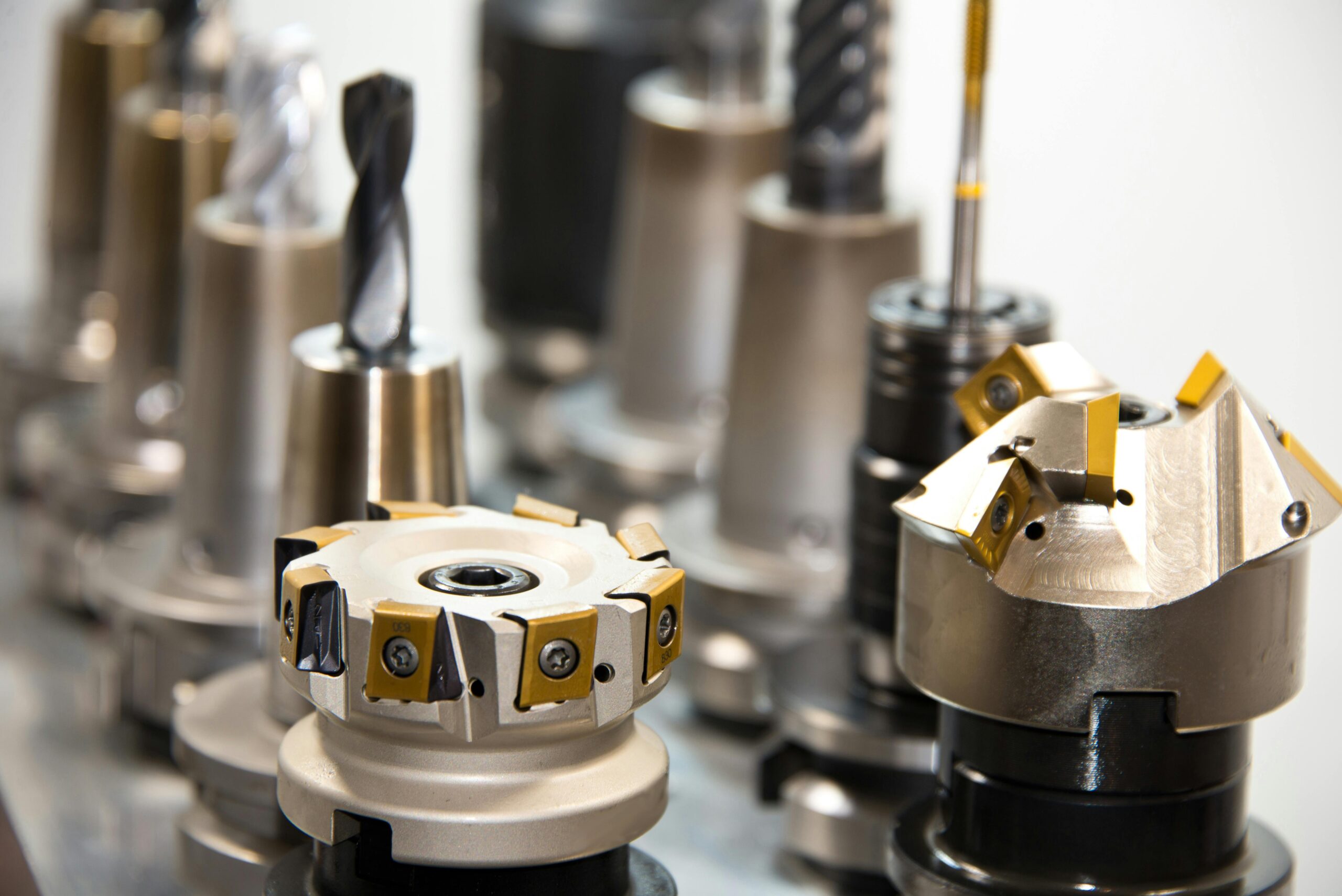

Carbide tools with sharp cutting edges perform exceptionally well with titanium. Coated carbides featuring TiAlN (titanium aluminum nitride) or AlCrN (aluminum chromium nitride) coatings provide enhanced heat resistance and reduced friction. These coatings create a barrier between the tool and workpiece, allowing for slightly more aggressive parameters.

Tool geometry matters enormously. Positive rake angles reduce cutting forces, while adequate relief angles prevent rubbing. Sharp tools are non-negotiable – dull tools generate excessive heat and accelerate work hardening, creating a downward spiral of poor surface finish and rapid tool wear.

🔥 Conquering Inconel: The Superalloy That Fights Back

Inconel and other nickel-based superalloys earn their reputation as the most challenging materials to machine. These materials maintain their strength at temperatures exceeding 1000°C, which means the heat generated during machining doesn’t soften the workpiece as it does with most metals.

Understanding Work Hardening Behavior

The primary challenge with Inconel is its tendency to work harden rapidly during machining. Each pass of the cutting tool creates a hardened layer on the surface that the next pass must cut through. This phenomenon accelerates tool wear and can quickly ruin cutting edges if not properly managed.

The solution involves maintaining consistent chip load and avoiding rubbing or dwelling in the cut. Once you engage the material, maintain feed rate and depth of cut. Hesitation or variable feed creates hardened spots that destroy tools and compromise surface finish.

Cutting Strategies for Long Tool Life

Ceramic and CBN (cubic boron nitride) tools excel at high-speed Inconel machining, while carbide grades specifically designed for superalloys work well at conventional speeds. The choice depends on your machine’s capabilities and the specific Inconel grade you’re processing.

Coolant strategy is crucial. High-pressure coolant delivery directly to the cutting zone removes heat and prevents chip rewelding. Through-tool coolant systems provide superior results compared to flood coolant, as they deliver cooling fluid precisely where needed most.

| Material | Recommended SFM | Feed Rate | Preferred Tool Material |

|---|---|---|---|

| Titanium (Ti-6Al-4V) | 50-80 | 0.004-0.012 IPT | Coated Carbide |

| Inconel 718 | 30-60 | 0.003-0.008 IPT | Ceramic/CBN/Carbide |

| CFRP Composites | 300-600 | 0.002-0.006 IPT | PCD/Diamond |

Composite Materials: A Different Beast Entirely 🎯

Carbon fiber reinforced polymers (CFRP) and other composite materials present challenges fundamentally different from metallic materials. The heterogeneous structure means you’re simultaneously cutting fibers with extreme abrasiveness and a matrix material with completely different properties.

Preventing Delamination and Fiber Pullout

The most common defects in composite machining are delamination (separation of layers) and fiber pullout. These occur when cutting forces exceed the bond strength between fibers and matrix material. Sharp tools with proper geometry minimize these forces.

PCD (polycrystalline diamond) tools represent the gold standard for composite machining. Diamond’s extreme hardness resists the abrasive wear that carbon fibers inflict on conventional tools. While expensive initially, PCD tools last dramatically longer than carbide when machining composites, reducing cost per part substantially.

Dust Control and Health Considerations

Machining composites generates fine dust that poses health risks and can damage equipment. Professional composite machining requires effective dust collection systems. These aren’t optional accessories but essential equipment for safe, sustainable operations.

Coolant use with composites requires careful consideration. Some matrix materials absorb moisture, which can affect dimensional stability and mechanical properties. Dry machining with vacuum dust collection often produces better results than wet machining, particularly for aerospace applications with strict moisture content specifications.

💡 Advanced Techniques for Professional Results

Moving beyond basic parameters, several advanced techniques separate exceptional results from merely acceptable ones. These methods require investment in equipment and process development but deliver returns through improved productivity and part quality.

High-Speed Machining Strategies

When properly implemented, high-speed machining transforms productivity with difficult materials. This approach uses higher spindle speeds combined with smaller radial and axial depths of cut. The principle involves removing material through many light passes rather than fewer heavy cuts.

Trochoidal milling exemplifies this strategy. The tool follows a circular path while advancing forward, maintaining constant tool engagement and distributing heat over the cutting edge. This technique works exceptionally well with Inconel and titanium, reducing cutting forces and extending tool life.

Cryogenic Cooling: The Future Is Cold

Cryogenic machining uses liquid nitrogen or carbon dioxide to cool the cutting zone to extremely low temperatures. This innovative approach produces remarkable results with titanium and Inconel. The extreme cold prevents work hardening, enables higher cutting speeds, and dramatically extends tool life.

While cryogenic systems represent significant investment, the technology is becoming more accessible. For high-volume production of difficult materials, the productivity gains and tool cost savings justify the capital expenditure.

🛠️ Toolpath Optimization and CAM Programming

Even perfect cutting parameters fail if toolpaths create unfavorable conditions. Modern CAM software offers sophisticated toolpath strategies specifically designed for difficult materials, but these features require understanding to use effectively.

Maintaining Consistent Chip Load

Variable chip load is the enemy of successful machining with challenging materials. Traditional toolpaths often create dramatic variations in chip load at corners and during tool engagement. Advanced CAM strategies maintain constant engagement angle and chip load throughout the toolpath.

Dynamic milling strategies, available in leading CAM packages, automatically adjust feedrate based on instantaneous engagement angle. This maintains constant cutting forces and prevents the sudden load changes that break tools or create work-hardened zones.

Entry and Exit Strategies

How tools enter and exit cuts significantly impacts surface quality and tool life. Plunging directly into Inconel or titanium invites disaster. Helical or ramped entries gradually engage the tool, preventing shock loading. Similarly, proper exit strategies prevent burr formation and edge chipping.

Corner rounding techniques prevent the sudden direction changes that cause tool deflection and poor surface finish. Instead of sharp 90-degree corners, toolpaths with rounded corners maintain cutting momentum and consistent chip formation.

Quality Control and Measurement Challenges 📊

Producing parts is only half the challenge – verifying they meet specifications presents additional complications with advanced materials. Composites particularly require specialized measurement approaches due to their flexible nature and potential for subsurface damage.

Surface Finish Verification

Surface roughness specifications for aerospace components are increasingly demanding. Achieving and verifying Ra values below 32 micro-inches requires proper measurement techniques. Contact profilometers work well for metals, but composites may require optical measurement to avoid damage from stylus pressure.

Visual inspection remains important, particularly for composites where fiber orientation and matrix quality affect performance. Training personnel to recognize acceptable versus defective surface conditions is crucial for maintaining quality standards.

Troubleshooting Common Problems Like a Pro 🔍

Even experienced machinists encounter problems when working with difficult materials. Systematic troubleshooting based on understanding failure modes leads to quick resolution rather than trial-and-error approaches.

Excessive Tool Wear

Rapid tool wear typically indicates excessive heat generation, incorrect tool selection, or work hardening. With titanium, increasing feed rate while reducing speed often extends tool life. For Inconel, verify coolant delivery is reaching the cutting zone effectively.

If tools wear unevenly, examine runout and machine rigidity. Difficult materials punish any mechanical deficiencies that would go unnoticed machining mild steel.

Poor Surface Finish

Surface finish problems have multiple potential causes. Built-up edge formation, common with titanium, indicates insufficient cutting speed or coolant effectiveness. Chatter marks suggest insufficient rigidity or incorrect tool selection. Delamination in composites signals excessive cutting forces or dull tools.

Systematic elimination of variables identifies root causes. Change one parameter at a time and document results. This disciplined approach builds knowledge that applies across multiple jobs.

🚀 Pushing Boundaries: Emerging Technologies

The machining industry continues evolving with new technologies that expand what’s possible with difficult materials. Staying current with these developments provides competitive advantages and opens new opportunities.

Ultrasonic-Assisted Machining

Ultrasonic vibration applied to cutting tools reduces cutting forces significantly when machining titanium and composites. The vibration creates intermittent cutting action that reduces friction and heat generation. This technology is transitioning from research to practical application in production environments.

Hybrid Manufacturing Approaches

Combining additive manufacturing with traditional machining creates new possibilities for complex parts in titanium and Inconel. Near-net-shape parts created through directed energy deposition or powder bed fusion require finish machining. Understanding both processes enables designers to optimize part geometry for manufacturability.

Building Your Expertise: Continuous Improvement

Mastering difficult materials requires commitment to ongoing learning. Technology advances rapidly, and techniques that were cutting-edge five years ago may now be outdated. Successful machinists invest in education through industry conferences, technical publications, and networking with peers facing similar challenges.

Documentation of successful processes creates institutional knowledge that survives personnel changes. Recording cutting parameters, tool selections, and results for each job builds a reference library invaluable for future work. Digital process sheets with photos and videos capture details that written descriptions miss.

Experimentation within controlled boundaries drives improvement. Allocating time for testing new tools, techniques, or parameters pays dividends through enhanced productivity and capabilities. The key is structured experimentation with clear objectives and proper documentation of results.

The Professional Mindset: Precision Over Speed

Working with titanium, Inconel, and composites demands a different mindset than conventional machining. These materials punish aggressive approaches and reward patience, precision, and proper technique. Rushing leads to scrap parts and broken tools that cost far more than the time saved.

Professional machinists understand that seemingly slower approaches often produce parts faster overall when setup time, tool changes, and scrap are considered. A conservative first operation that completes successfully beats an aggressive approach requiring multiple tool changes and potential rework.

Investment in proper equipment, tooling, and training isn’t expense – it’s essential infrastructure for competitive operations. Organizations that treat difficult materials as opportunities rather than obstacles build reputations that command premium pricing and attract the most interesting projects.

The challenges of machining advanced materials create barriers that protect skilled professionals from commoditization. While basic machining becomes increasingly automated, titanium, Inconel, and composites still require human expertise to produce consistently excellent results. Mastering these materials provides career security and professional satisfaction that few other manufacturing specialties offer.

Toni Santos is a manufacturing systems researcher and sustainable production specialist focusing on carbon-neutral materials, clean micro-manufacturing processes, digital precision machining, and sustainable batch systems. Through an interdisciplinary and efficiency-focused lens, Toni investigates how advanced manufacturing can integrate ecological responsibility, precision engineering, and resource optimization — across industries, scales, and production paradigms. His work is grounded in a fascination with manufacturing not only as production, but as carriers of environmental impact. From carbon-neutral material innovation to clean micro-manufacturing and digital precision systems, Toni uncovers the technical and operational tools through which industries can achieve their transition toward sustainable production practices. With a background in manufacturing engineering and sustainable production systems, Toni blends technical analysis with environmental research to reveal how materials can be sourced responsibly, machined precisely, and processed sustainably. As the creative mind behind fynvarox, Toni curates precision manufacturing insights, carbon-neutral material studies, and sustainable batch system strategies that advance the integration between industrial efficiency, digital accuracy, and ecological integrity. His work is a tribute to: The responsible sourcing of Carbon-Neutral Materials and Processes The precision methods of Clean Micro-Manufacturing Technologies The accuracy and control of Digital Precision Machining The resource-efficient design of Sustainable Batch Production Systems Whether you're a manufacturing engineer, sustainability researcher, or curious practitioner of responsible production, Toni invites you to explore the future of clean manufacturing — one material, one process, one system at a time.