Modern machining demands precision, speed, and reliability. In-process sensing technology is transforming manufacturing by delivering real-time data that optimizes performance and eliminates costly errors.

🔧 The Evolution of Manufacturing Intelligence

The manufacturing landscape has undergone a dramatic transformation over the past decade. Traditional machining processes relied heavily on pre-set parameters, periodic inspections, and post-production quality checks. This reactive approach often resulted in wasted materials, increased downtime, and inconsistent product quality. The integration of in-process sensing technology represents a paradigm shift from reactive to proactive manufacturing strategies.

In-process sensing systems continuously monitor machining operations in real-time, providing immediate feedback about tool condition, workpiece quality, and process stability. This technological advancement enables manufacturers to identify potential issues before they escalate into costly problems, fundamentally changing how production floors operate.

The implementation of these sophisticated systems has become increasingly accessible, with solutions ranging from simple vibration sensors to complex multi-sensor arrays that monitor temperature, acoustic emissions, force, and dimensional accuracy simultaneously. This democratization of advanced sensing technology means that businesses of all sizes can now benefit from intelligent manufacturing solutions.

Understanding In-Process Sensing Technology Architecture

In-process sensing technology comprises several interconnected components working harmoniously to deliver actionable intelligence. At its core, the system includes physical sensors mounted on or near machining equipment, data acquisition hardware that converts analog signals to digital information, and sophisticated software that analyzes this data to provide meaningful insights.

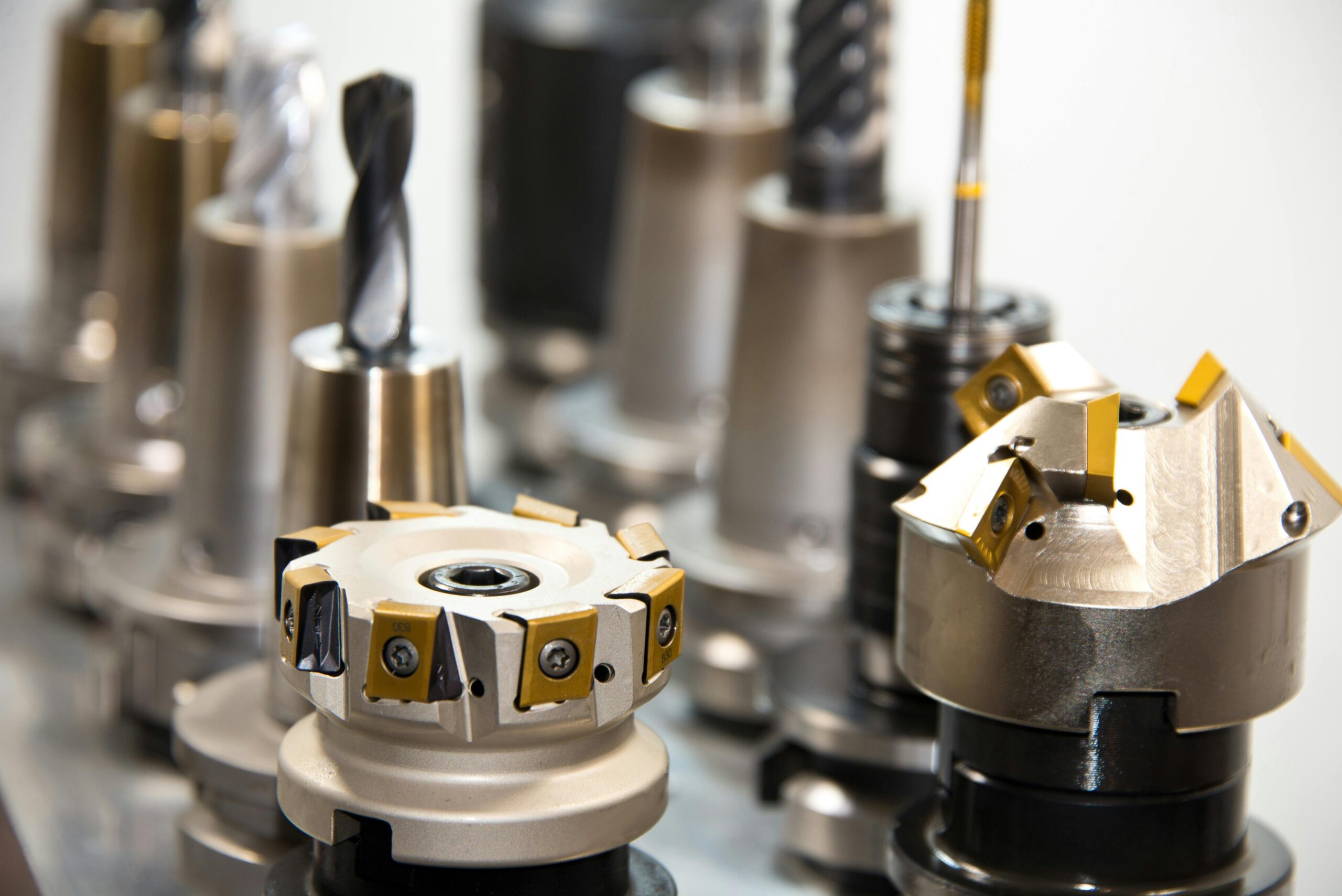

The sensor selection depends on the specific monitoring requirements. Accelerometers detect vibrations that indicate tool wear or chatter, thermocouples monitor temperature changes that affect dimensional accuracy, dynamometers measure cutting forces that reveal material inconsistencies, and acoustic emission sensors identify microscopic crack formation or tool breakage events.

Modern systems leverage edge computing capabilities, processing data locally to provide immediate feedback while simultaneously transmitting relevant information to cloud-based platforms for historical analysis and predictive modeling. This hybrid architecture ensures both rapid response times and comprehensive long-term optimization strategies.

⚡ Real-Time Monitoring Benefits That Transform Production

The immediate visibility into machining operations provided by in-process sensing creates multiple competitive advantages. Real-time monitoring enables operators to detect tool wear progression, allowing for predictive tool changes that prevent catastrophic failures and maintain consistent part quality throughout production runs.

Process stability monitoring identifies parameter drift before it affects part quality. When cutting conditions deviate from optimal settings, the system alerts operators or automatically adjusts machine parameters to maintain performance specifications. This continuous optimization reduces scrap rates significantly while extending tool life.

Dimensional accuracy verification during machining cycles eliminates the need for extensive post-production inspection. In-process gauging systems measure critical features while parts remain fixtured, enabling immediate corrections if dimensions trend toward tolerance limits. This approach drastically reduces the time between manufacturing and quality verification.

Precision Enhancement Through Adaptive Control Systems

Adaptive control represents the pinnacle of in-process sensing application. These systems don’t merely monitor machining processes—they actively intervene to maintain optimal conditions. When sensors detect changes in cutting forces due to material hardness variations, the control system automatically adjusts feed rates or spindle speeds to maintain consistent chip load and surface finish quality.

Thermal compensation systems use temperature sensor data to predict and counteract thermal growth in machine structures and workpieces. As machines warm up during production, their components expand, potentially causing dimensional inaccuracies. Adaptive systems calculate these thermal effects in real-time and apply corrective positioning adjustments, maintaining micron-level accuracy throughout extended production runs.

Chatter suppression systems represent another sophisticated application. When vibration sensors detect the onset of regenerative chatter—a self-excited vibration that destroys surface finish and damages tools—the control system modifies spindle speed to break the resonance cycle, maintaining stable cutting conditions automatically.

🎯 Strategic Implementation for Maximum ROI

Successfully integrating in-process sensing technology requires careful planning and phased implementation. Begin by identifying critical operations where quality issues, tool failures, or process instability create the most significant production challenges. These pain points represent the highest-value opportunities for sensing technology deployment.

Pilot projects provide valuable learning experiences without overwhelming manufacturing teams. Select a single machine or process for initial implementation, allowing operators and engineers to develop expertise with the technology before broader deployment. Document successes, challenges, and lessons learned to inform subsequent installations.

Training represents a critical success factor. Operators need to understand sensor outputs, interpret system alerts, and respond appropriately to monitoring data. Engineering teams require deeper knowledge about system configuration, threshold settings, and data analysis techniques. Investment in comprehensive training ensures that sensing technology delivers its full potential value.

Cost-Benefit Analysis and Financial Justification

While in-process sensing systems require upfront investment, the financial returns typically justify expenditures within 12 to 24 months. Reduced scrap rates alone often cover significant portions of implementation costs, particularly in high-value manufacturing environments where material costs represent substantial expenses.

Tool life extension provides additional savings. Predictive monitoring enables tools to be used to their full productive lifespan while avoiding costly breakage events. In high-volume production environments, extending tool life by even 15-20% generates substantial annual savings that accumulate across multiple machining centers.

Reduced machine downtime delivers perhaps the most significant financial impact. Unexpected tool failures create expensive interruptions that cascade through production schedules. Predictive monitoring prevents these disruptions, maintaining throughput consistency and enabling more reliable delivery commitments to customers.

📊 Data Analytics and Continuous Improvement

The historical data collected by in-process sensing systems creates a valuable repository for continuous improvement initiatives. Trend analysis reveals gradual process degradation that might otherwise go unnoticed until quality issues emerge. By identifying these subtle trends early, manufacturing teams can implement preventive interventions that maintain consistent performance.

Process optimization opportunities become visible through comparative analysis of sensing data across multiple production runs. Engineers can evaluate how parameter variations affect outcomes, systematically refining machining strategies to maximize efficiency while maintaining quality standards. This data-driven approach to process development accelerates optimization cycles significantly.

Predictive maintenance models leverage machine learning algorithms applied to sensor data streams. These models identify complex patterns that precede equipment failures, enabling maintenance teams to schedule interventions during planned downtime rather than responding to unexpected breakdowns. The transition from reactive to predictive maintenance reduces maintenance costs while improving equipment availability.

Integration With Industry 4.0 and Smart Manufacturing

In-process sensing technology serves as a foundational element of Industry 4.0 initiatives. The sensor data integrates seamlessly with manufacturing execution systems (MES), enterprise resource planning (ERP) platforms, and product lifecycle management (PLM) software, creating comprehensive digital threads that connect design intent with manufacturing reality.

Digital twin technology leverages real-time sensing data to maintain virtual replicas of physical machines and processes. These digital twins enable simulation and scenario testing without disrupting actual production, accelerating process development and troubleshooting activities. The convergence of physical sensing and virtual modeling creates powerful capabilities for manufacturing optimization.

Cloud connectivity enables remote monitoring and support, allowing engineering expertise to be shared across multiple facilities regardless of geographic distribution. Equipment manufacturers increasingly offer remote diagnostic services that leverage in-process sensing data to provide proactive support, identifying potential issues before customers experience production disruptions.

🛠️ Overcoming Implementation Challenges

Despite clear benefits, organizations sometimes encounter obstacles during sensing technology deployment. Harsh manufacturing environments can challenge sensor durability, requiring careful selection of industrial-grade components designed to withstand coolant exposure, metal chips, and temperature extremes. Protective housings and proper mounting techniques ensure reliable long-term operation.

Data overload represents another common challenge. Modern sensing systems can generate enormous volumes of information, potentially overwhelming operators and engineers. Successful implementations focus on extracting actionable insights rather than displaying raw data streams. Intelligent filtering, exception-based alerting, and clear visualization dashboards help users focus on information that requires attention.

Integration with legacy equipment sometimes requires creative solutions. Older machine tools may lack the connectivity interfaces found on modern CNC systems. Retrofit sensing solutions using standalone data acquisition systems and wireless connectivity can bring smart manufacturing capabilities to existing equipment without requiring wholesale machine replacement.

Future Trends and Emerging Technologies

The evolution of in-process sensing technology continues to accelerate. Miniaturization enables sensors to be embedded directly into cutting tools, providing unprecedented insight into conditions at the cutting edge. These smart tools wirelessly transmit data about temperature, vibration, and forces directly from the machining zone, enabling even more precise process control.

Artificial intelligence and machine learning algorithms increasingly power next-generation sensing systems. These advanced algorithms can identify complex patterns that human analysts might miss, automatically optimizing processes and predicting outcomes with remarkable accuracy. As these technologies mature, sensing systems will transition from monitoring and alerting to autonomous optimization with minimal human intervention.

Multi-modal sensing fusion combines data from diverse sensor types to create comprehensive process understanding. Rather than analyzing individual sensor streams independently, advanced systems synthesize information from vibration, acoustic, thermal, and force sensors simultaneously, recognizing complex signatures that indicate specific process states or emerging problems.

💡 Practical Applications Across Manufacturing Sectors

Aerospace manufacturers utilize in-process sensing to maintain the extreme tolerances required for critical flight components. The technology enables lights-out machining of complex titanium and nickel alloy parts, with systems automatically verifying dimensional accuracy and detecting tool wear that could compromise part integrity.

Medical device manufacturers leverage sensing technology to ensure the precision required for implantable components and surgical instruments. In-process verification provides documentation that supports regulatory compliance requirements while reducing inspection time and costs associated with these highly regulated products.

Automotive component manufacturers apply sensing technology across high-volume production lines, where consistency across thousands of identical parts is paramount. Real-time monitoring detects process variations immediately, preventing the production of large batches of defective components and reducing warranty claims related to manufacturing defects.

Building a Culture of Data-Driven Manufacturing

Technology alone doesn’t guarantee success—organizational culture plays an equally important role. Manufacturing teams must embrace data-driven decision-making, trusting sensor insights over intuition or traditional practices. Leadership support is essential in fostering this cultural transformation, demonstrating commitment through resource allocation and recognizing teams that effectively leverage sensing technology.

Cross-functional collaboration amplifies sensing technology value. When operators, engineers, quality professionals, and maintenance teams share sensor data and insights, collective intelligence emerges that drives more comprehensive improvements than any single department could achieve independently. Regular review meetings focused on sensor data analysis facilitate this collaborative approach.

Continuous learning environments ensure that organizations evolve alongside their sensing technology capabilities. As systems become more sophisticated and new analytical techniques emerge, ongoing training and knowledge sharing keep manufacturing teams at the forefront of intelligent manufacturing practices. This commitment to continuous learning transforms sensing technology from a tool into a competitive advantage.

🚀 Taking the First Step Toward Intelligent Machining

Organizations considering in-process sensing technology should begin with thorough assessment of current manufacturing challenges and opportunities. Engage with technology providers to understand available solutions and conduct facility assessments that identify high-value application opportunities. Many suppliers offer demonstration programs that allow evaluation of sensing systems on actual production equipment before purchase commitments.

Develop a phased implementation roadmap that aligns technology deployment with strategic manufacturing objectives. Prioritize applications that address critical quality issues, reduce significant costs, or enable new capabilities that support business growth. This strategic approach ensures that sensing technology investments deliver measurable business value rather than implementing technology for its own sake.

The transformation of machining processes through in-process sensing technology represents more than incremental improvement—it fundamentally redefines what’s possible in manufacturing. Organizations that embrace these intelligent systems position themselves to compete effectively in markets that increasingly demand higher quality, greater flexibility, and faster delivery. The journey toward intelligent machining begins with a single sensor, but leads to comprehensive manufacturing excellence that drives sustainable competitive advantage for years to come.

Toni Santos is a manufacturing systems researcher and sustainable production specialist focusing on carbon-neutral materials, clean micro-manufacturing processes, digital precision machining, and sustainable batch systems. Through an interdisciplinary and efficiency-focused lens, Toni investigates how advanced manufacturing can integrate ecological responsibility, precision engineering, and resource optimization — across industries, scales, and production paradigms. His work is grounded in a fascination with manufacturing not only as production, but as carriers of environmental impact. From carbon-neutral material innovation to clean micro-manufacturing and digital precision systems, Toni uncovers the technical and operational tools through which industries can achieve their transition toward sustainable production practices. With a background in manufacturing engineering and sustainable production systems, Toni blends technical analysis with environmental research to reveal how materials can be sourced responsibly, machined precisely, and processed sustainably. As the creative mind behind fynvarox, Toni curates precision manufacturing insights, carbon-neutral material studies, and sustainable batch system strategies that advance the integration between industrial efficiency, digital accuracy, and ecological integrity. His work is a tribute to: The responsible sourcing of Carbon-Neutral Materials and Processes The precision methods of Clean Micro-Manufacturing Technologies The accuracy and control of Digital Precision Machining The resource-efficient design of Sustainable Batch Production Systems Whether you're a manufacturing engineer, sustainability researcher, or curious practitioner of responsible production, Toni invites you to explore the future of clean manufacturing — one material, one process, one system at a time.