Enhance Precision with Digital Twins

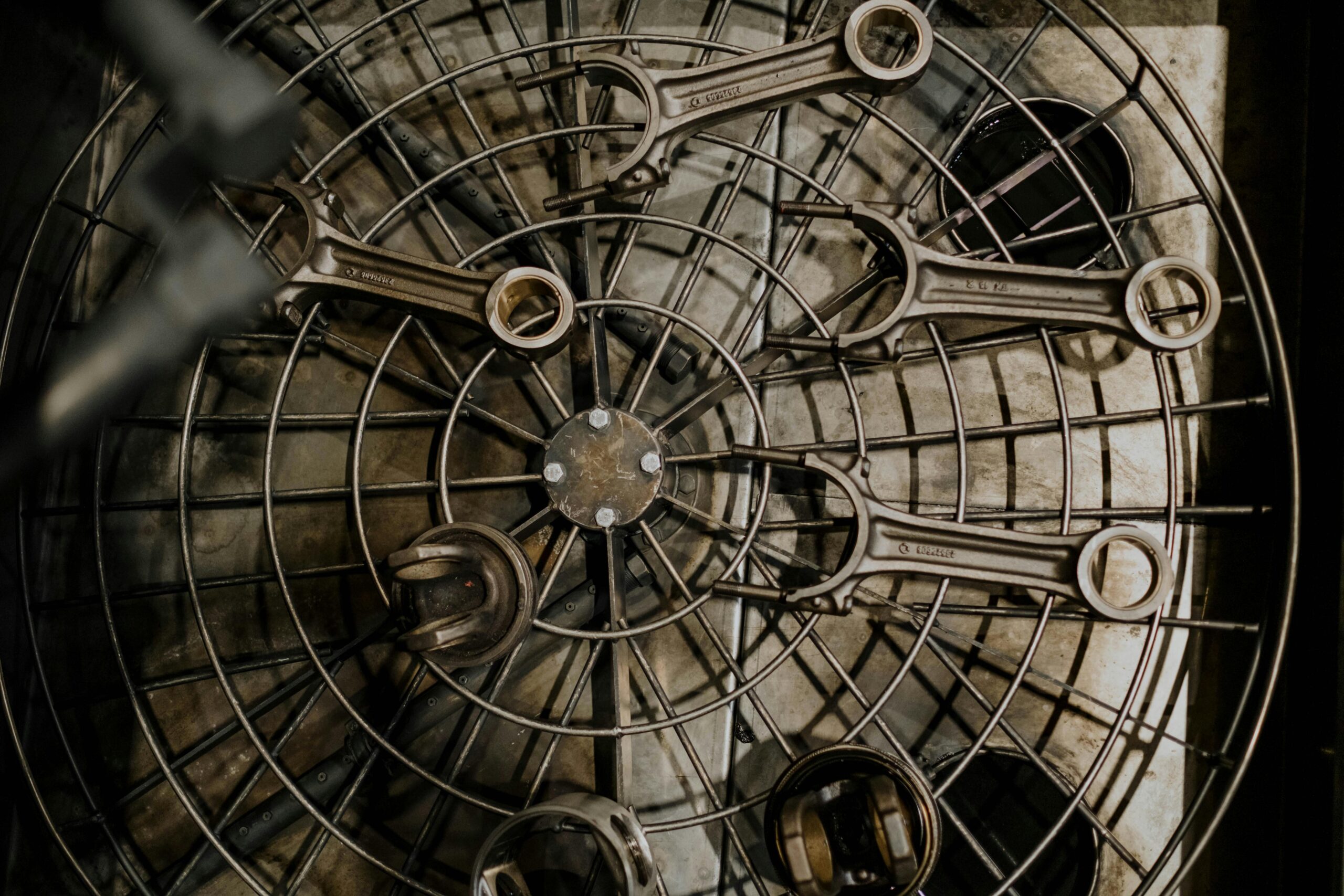

Digital twin technology is revolutionizing manufacturing by creating virtual replicas of physical machining processes, enabling unprecedented precision and efficiency in production

Digital twin technology is revolutionizing manufacturing by creating virtual replicas of physical machining processes, enabling unprecedented precision and efficiency in production

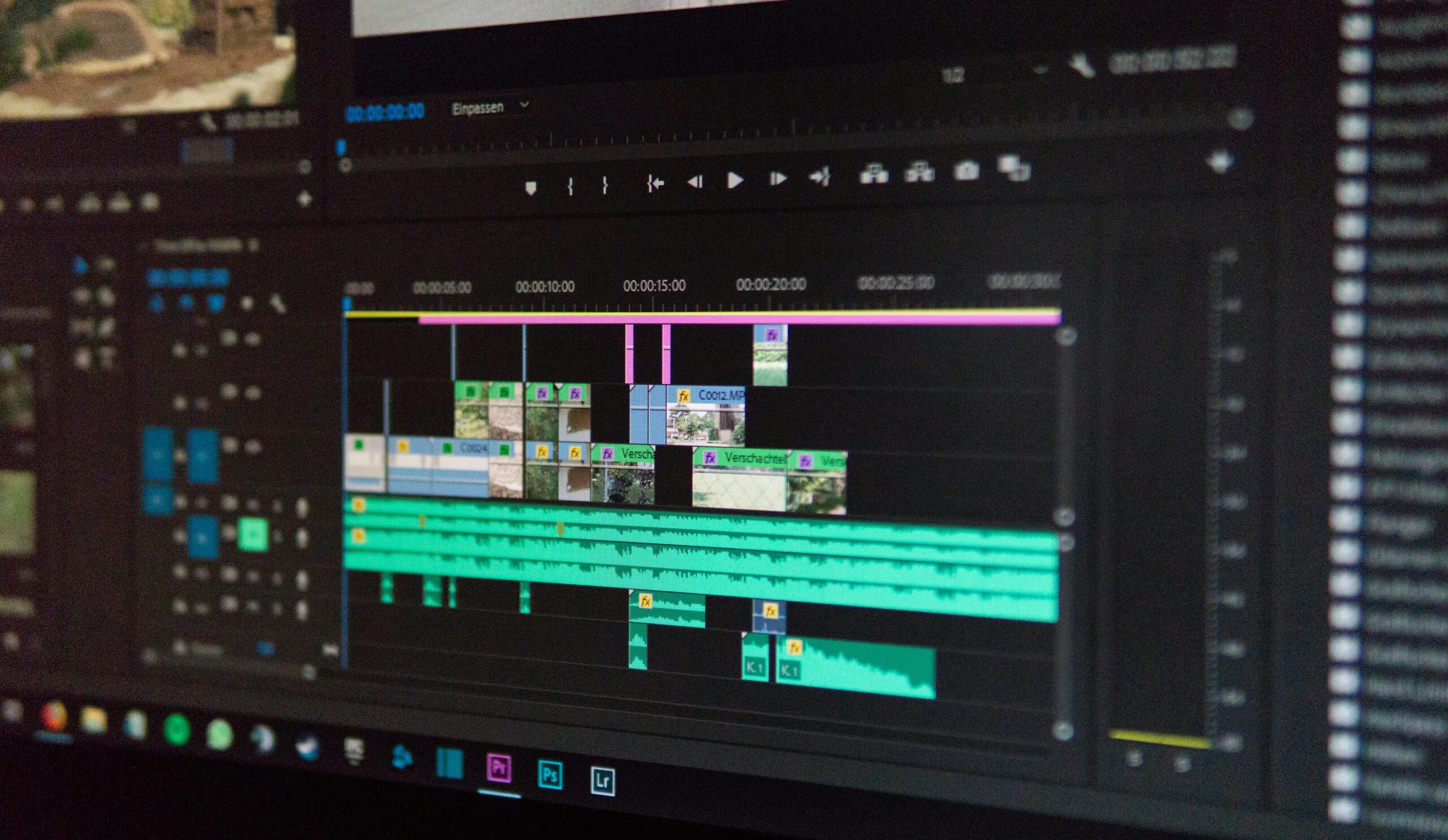

The convergence of digital technologies and traditional manufacturing is transforming how precision components are designed, produced, and delivered in the modern

Surface finishing in modern manufacturing demands precision, consistency, and efficiency—qualities that artificial intelligence now delivers through intelligent parameter optimization and real-time

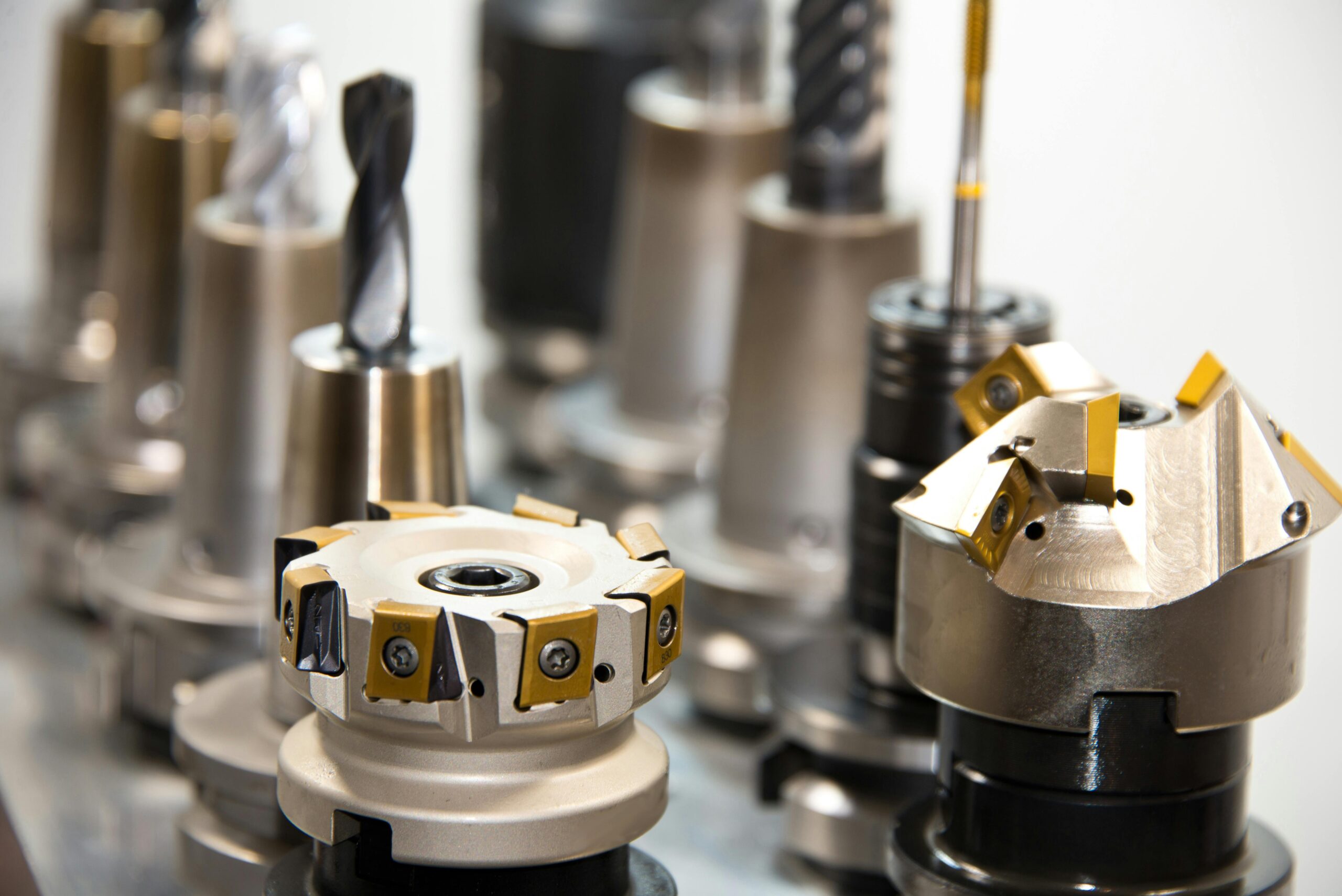

Precision machining operations demand consistent performance, minimal downtime, and maximum efficiency. Predictive maintenance is revolutionizing how manufacturers approach tool management and

Modern manufacturing demands unprecedented accuracy, where even the smallest deviation can mean the difference between perfection and failure in high-stakes industries.

In today’s hyper-connected manufacturing landscape, metrology integration has become the cornerstone of achieving unprecedented precision, productivity, and competitive advantage in digital

Modern manufacturing thrives on seamless digital integration. From initial design to final inspection, the journey through CAD, CAM, and QA workflows

Machining advanced materials like titanium, Inconel, and composites demands precision, expertise, and the right approach to achieve professional results consistently. 🔧

Surface roughness is the invisible detail that defines product quality, functionality, and user experience in modern manufacturing. Whether you’re working in

Precision machining demands meticulous planning and execution where every micrometer counts. Error budgeting has emerged as the cornerstone methodology for achieving